New Standards in Traceability, Hygiene, and Operational Safety in the Food Industry

The food industry, being directly related to public health, is one of the sectors that requires the highest standards of hygiene, quality, and traceability. ProManage MES fully digitalizes production processes, thereby enhancing operational safety and minimizing food safety risks.

From raw material intake to final product shipment, all stages are monitored in real-time and without interruption. By tracking critical lot information, filling and packaging controls, and process variables such as temperature, vibration, pressure, and humidity, ProManage automates production operations and minimizes human error.

ProManage monitors production plans live, ensures synchronization of in-line operations, prevents delays, and reduces scrap rates, leading to increased efficiency and profitability.

By facilitating compliance with international standards such as GMP (Good Manufacturing Practices), it accelerates certification and audit processes. Thus, it helps establish a safe, transparent, and competitive production environment for both domestic and export markets.

With ProManage, ensure food safety in production, increase efficiency, and build lasting consumer trust.

Gains Achieved with ProManage MES in the Food Industry

- Real-time production monitoring ensures instant coordination among planning, quality, and production teams

- Digital tracking of critical process variables like temperature, pressure, and humidity minimizes food safety risks

- Lot and traceability management accelerate recall processes and simplify regulatory compliance

- Root cause analysis of downtime reduces losses due to malfunctions and waiting times

- A paperless production environment improves data accuracy and enhances audibility

- Visibility into operator performance fuels suggestion systems and strengthens continuous improvement culture

- OEE and production efficiency increase while scrap rates decrease through in-line synchronization

- Integration with ERP systems creates a fully digital end-to-end production environment

- Investments typically pay for themselves within 1 year

One Page

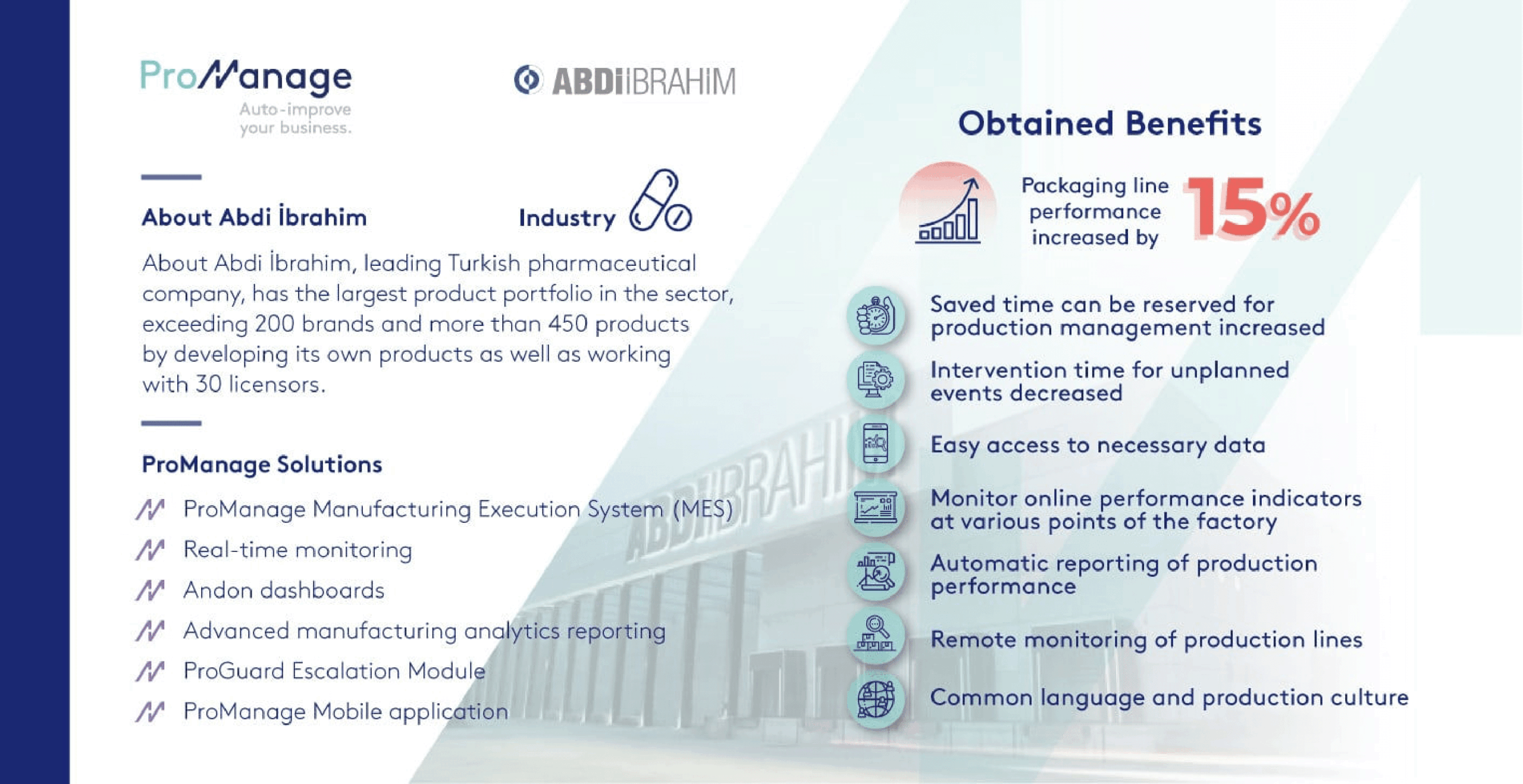

Abdi İbrahim

About Abdi İbrahim, leading Turkish pharmaceutical company, has the largest product portfoilo in the sector, exceeding 200 brands and more than 450 products by developing its own products as well as working with 30 licensors.

Schedule Your Demo

ProManage experts will answer your questions and provide more information about the platform with a live demonstration. To obtain further information about our platform, fill out the form and we will promptly reach out to you.